-

Global

-

Africa

-

Asia Pacific

-

Europe

-

Latin America

-

Middle East

-

North America

- |

- BUSINESSES

- |

- Contact

- |

-

Global

-

Africa

-

Asia Pacific

-

Europe

-

Latin America

-

Middle East

-

North America

- |

- BUSINESSES

- |

- Contact

- |

You are browsing the product catalog for

You are viewing the overview and resources for

- News

- How Quantum Computing Can Help Nippon Steel Improve Scheduling at Plants

How Quantum Computing Can Help Nippon Steel Improve Scheduling at Plants

The global steel manufacturer collaborated with Cambridge Quantum Computing and Honeywell Quantum Solutions to optimize scheduling.

Over the past several months, consumers have experienced firsthand what happens when manufacturing and supply chains are disrupted.

Toilet paper, canned foods, and hand sanitizer were scarce early in the COVID-19 pandemic. At the same time, other goods stacked up at ports and in storage as non-essential businesses closed and millions of people quarantined.

Luckily, such extreme disruptions are rare. Nevertheless, it highlighted the complexity of managing global manufacturing and supply chains. Manufacturers constantly juggle supply and demand, availability of raw goods, weather and other factors.

This is true at Nippon Steel, one of the largest steel manufacturers in the world. The Tokyo-based company manufactured more than 50 million metric tons of steel products in 2019.

Nippon Steel has long invested in advanced computing and technology to help employees optimize scheduling and maximize efficiency. Now, it is exploring how quantum computing can help.

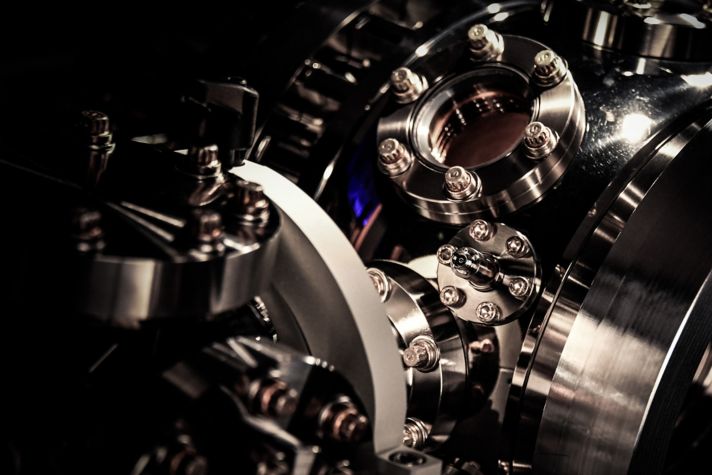

The company collaborated with Cambridge Quantum Computing (CQC) to devise an optimal schedule for the intermediate products it uses during the steel manufacturing process. They developed an algorithm and ran it on the System Model H1, Honeywell Quantum Solutions’ latest commercial computer.

“Scheduling at our steel plants is one of the biggest logistical challenges we face, and we are always looking for ways to streamline and improve operations in this area,” said Koji Hirano, chief researcher at Nippon Steel.

A complex problem

Manufacturing steel is a multi-step process that has remained largely the same for decades. Plants start by processing iron ore, coal, and other material into slabs of steel (an alloy of iron and carbon) that are then converted into products.

Having the right amount of raw materials and intermediate products on site to complete orders is a balancing act. Add in factors such as multiple orders, order type (grade of steel) and size, production count, deadlines and other specifications and the complexity of operating a steel plant significantly ratchets up.

Streamlining or optimizing the production process and scheduling is challenging given the number of variables. But it also represents an area in which to make significant gains in efficiency and reduce operating costs.

This challenge is not unique to steel manufacturing. Similar combinatorial optimization problems are ubiquitous throughout global manufacturing, transportation industries, and distribution systems in which goods and services move through several steps.

Finding optimal solutions is difficult even with today’s supercomputers. Quantum computers harness certain quantum physics phenomena to represent multiple solutions at once and find the best one, which makes them uniquely suited to tackle such optimization challenges.

Promising results

However, today’s quantum systems are still early stage and cannot yet solve for all the variables present so CQC and Nippon Steel formulated a representative problem. The System Model H1 was able to find the optimal solution after only a few steps.

“The results are encouraging for scaling up this problem to larger instances,” said Mehdi Bozzo Rey. “This experiment showcases the capabilities of the System Model H1 paired with modern quantum algorithms and how promising this emerging technology really is.”

Tony Uttley, president of Honeywell Quantum Solutions, said such collaborations demonstrate how companies can start using quantum computers to tackle complex, real-world problems.

“The results Nippon Steel and Cambridge Quantum Computing were able to achieve indicate that quantum computing will be a powerful tool for companies seeking a competitive advantage,” he said.

Expanded capabilities

Earlier this month, Honeywell Quantum Solutions announced that it will combine with Cambridge to form the world’s largest stand-alone quantum computing company.

For Ilyas Khan, CEO and founder of CQC, and Uttley, the project with Nippon Steel illustrates the type of global challenges the new company will focus on solving.

“An efficient and effective supply chain is critical to society and any interruption in the chain can have vast repercussions down the line,” Khan said. “Honeywell and CQC are eliminating such interruptions via quantum computing and we look to apply this work across industries as we come together as one company.”

Copyright © 2026 Honeywell International Inc.